Depositor

It deposits the filling material onto the dough sheet or trays moving on the production line.

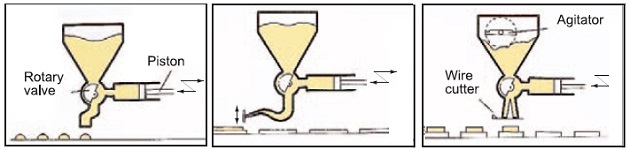

There are two types of deposit forms.

Choose the right depositor for your production process, products and capacity requirements from our wide range of line-up.

Features

Choose the right depositor for your products

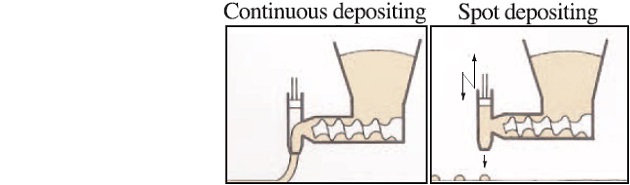

"Continuous Deposit" continuously extrudes the material in the form of lines onto the moving dough sheet.

"Spot Deposit" deposits the material individually in round or oblong shape. Because of the air drive system for "Spot Deposit", the material receives no excess pressure.

By this system, the material is deposited stably and the uniform production is achieved with a wide range of material application.

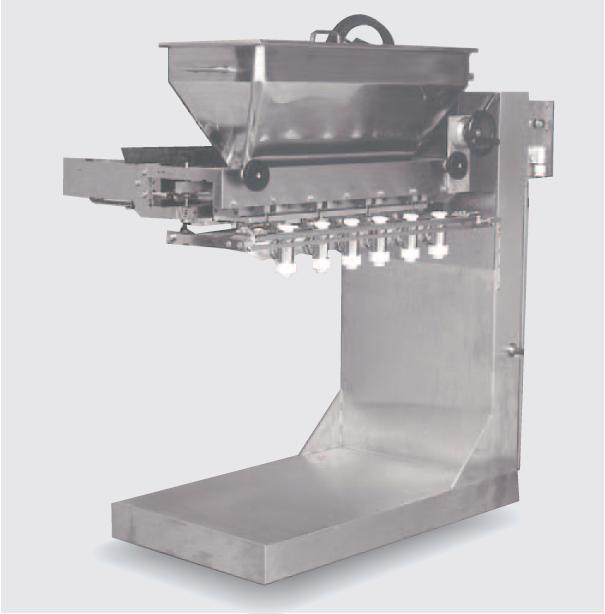

1) Rotary Valve Type Depositor

Spot Depositor for soft and fluid material.

The shape of the deposit can vary according to nozzle and speed.

The machine can be equipped with an agitator for the materials which tend to create a bridge in the hopper.

Spot Type

| Depositing amount | Max. depositing frequency | Nozzle Pitch | Max. dough width |

|---|---|---|---|

| 15 – 40cc | 40 times/min | 100mm, 85mm, 70mm |

MD201 : 400mm MD202 : 600mm MD203 : 800mm |

Long spot type (Custom order)

| Max. depositing capacity | Max. depositing frequency |

|---|---|

| 300cc/deposit | 13 times/min |

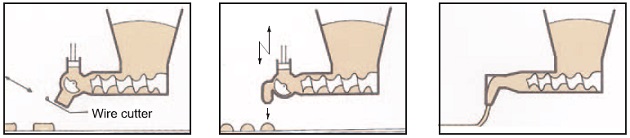

Butter cream with cutter (Custom order)

| Depositing capacity | Depositing frequency |

|---|---|

| 8 – 20cc | 40 times/min |

2) Continuous Screw Type Depositor

Continuous Depositor with screw feeder. Select the number of rows or deposit shapes by changing nozzle. The machine can be equipped with an agitator.

| Depositing capacity | Nozzle pitch | Max. dough width |

|---|---|---|

| Depositing amount is adjustable within 0.2 – 1.5kg/min per nozzle | 100mm |

MD011 : 400mm MD012 : 600mm MD013 : 800mm |

3) Piston and Screw Type Depositor

Continuous and Spot Depositor. It has the same ability for continuous depositing as screw type machines.

Softer materials are suitable for spot depositing because of piston action.

|

Depositing capacity (Continuous) |

Depositing capacity (Spot) |

Max. dough width |

|---|---|---|

|

Depositing amount is adjustable |

Min.space = Belt speed (mm/min) / 40 Max.space = Belt speed (mm/min) / 13 |

MD101 : 400mm MD102 : 600mm MD103 : 800mm |

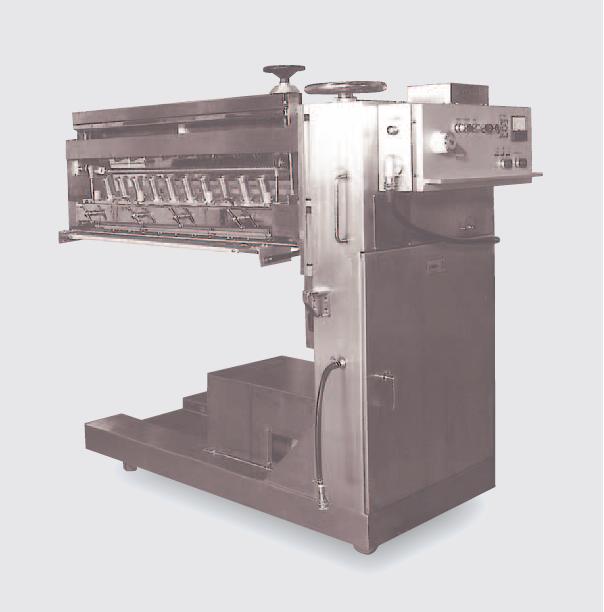

4) Valve and Screw Type Depositor

Continuous and Spot Depositor for harder material. This machine can also perform the same function as the continuous screw depositor.

|

Depositing capacity (Continuous) |

Depositing capacity (Spot) |

Max. depositing frequency | Max. dough width |

|---|---|---|---|

|

Adjustable within 0.6 – 1.4kg/min per nozzle (20mm diameter) |

One nozzle deposits 15 – 35g per deposit |

40 times / min |

MD301 : 400mm MD302 : 600mm MD303 : 800mm |

Contact nearest Rheon office for a custom order.

For the actual result, confirm by running the test with your own ingredient at the Rheon office near you.

▲Apple pie