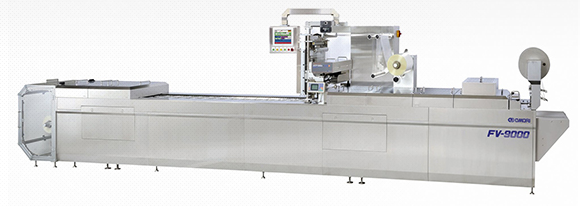

FV-9000 – High Spec & Upgraded Hygiene

Features

-

Easy chamber replacement

Trolley system for forming and vacuum chambers. Sliding drawer chamber replacement option.

-

Safety design

Active matrix TFT color touch screen display with diagnostics assures effortless operation. Adjsutable position for ease of view and operation.

-

10.4" color touch screen control

-

Accurate print registration (OPTION)

The bottom film is servomotor driven, allowing very accurate film feed adjustment. Film feed pitch can be adjusted in 0.1mm steps. Print registration is simple and accurate and, as an option, the machine can be handle bottom film with eye-marks.

-

Multiple package styles

Vacuum pack, MAP pack, blister pack, skin pack, steam shrink pack, hot pack, etc.

-

Various types of date coder (OPTION)

Multi-lane thermal transfer date coder is available.

-

Factory automation

The machine's control system is designed to simplify connection and synchronization with upstream and downstream equipment such as automatic product feeders, wrap-around cartoner, set-up caser, slicer, etc.

Specifications

| Speed (Max.) |

Vacuum pack : Max. 10 cycles/min. Gas (MAP) pack : Max. 8 ~ 10cycles/min. Form & pack : Max. 10 cycles/min. *Varies according to product, format, etc. |

|---|---|

| Width of base film |

Type A : 370 ~ 420 mm Type B : 420 ~ 470 mm Type C : 470 ~ 520 mm Type D : 520 ~ 570 mm Type E : 570 ~ 620 mm |

| Film Type |

Lid: Heat sealable plastic films Base: Thermoformable and heat sealable plastic film Maximum O.D. of roll film: 370mm |

| Pressing depth | Max. 130 mm |

| Products | Foods (solid, liquid, paste). Medical & Pharmaceutical items, Industrial products |

| Machine length |

4,300mm (Standard) 5,300mm (1,000mm long) 6,300mm (2,000mm long) |

| Forming systems | Thermoforming with vacuum and compressed air |

| Sealing method | Heat sealing |

| Print registration | Photocell / servomotor control |

| Film feeding | Servomotor driven intermittent feed |

| Cross cutting system | Pneumatic driven cross-cut type |

| Longitudinal slit system | Motor driven circular knives |

| Film trim remover | Rewind type scrap removal system or cut type |

| Compressed air | 0.6Mpa Approx. 130 litre/cycle *Varies according to specification. |

| Water cooling | 0.2 – 0.3 Mpa, 4 – 5 litre/min. |

| Power consumption | 3ph., AC200V, 10 KVA, 50/60Hz *Varies according to specification. |

| Machine weight | Approx. 1,500Kgs. |

*Specifications are subject to change depending on product and film.

Optional equipment

- Discharge belt conveyor

- Plug-assist forming

- Drape forming

- Bottom film print registration

- Gas flushing (MAP) system

- Sauce filled pack

- Skin pack system

- Perforation cutting system

- Round corner cutting system

- Trimming system

- I-notch cutter system

- Cooling system

- Automatic gripper chain cleaning system

- Air chuck type film bobbin

- Date coder

- Coding check device