Discover How You Can Start Rolling Perfect Sushi Like A Sushi Chef In Minutes… Even If You’ve Never Made Sushi Before

The secret “Sushi Chef” used by HUNDREDS of successful sushi shops, trains, franchises, and wholesalers, including Sushi Sushi, Go Sushi, Wasabi Warriors, Wok Me, Sushi Hub, Hero Sushi, and many more…

If you’ve ever wanted to start a sushi business, but have hesitated at the idea because you’ve never made sushi before…

Or if you currently make sushi by hand, and need a way to make better quality sushi, faster and more consistently…

You are not alone.

In fact, thousands of sushi businesses around the world have faced these same questions.

How do you keep up with hungry customers and roll hundreds of rolls of sushi every hour, and more importantly, roll high quality rolls consistently – no matter who is in the shop?

Now, before I answer that question, and reveal the technology developed by the Japanese to solve those problems – let’s look at some of the common problems that hold people back from starting, or running a successful sushi business:

[/text_block]

Problem #1: Rolling Sushi By Hand Can Be Slow

[op_liveeditor_element data-style=””]

Sushi rolls are traditionally rolled by hand. But the problem is: rolling by hand can be slow, ESPECIALLY if you or your staff aren’t experienced at making sushi.

This makes it harder to make enough sushi to keep up with customers!

And it makes it hard to make sushi fast enough to ensure that it is as FRESH and tasty for your customer (which keeps them coming back and buying from you).

Fortunately though, there is a better (and faster) alternative to rolling sushi by hand (and I’ll let you in on a little secret: the LARGEST and most SUCCESSFUL franchises in Australia like Sushi Sushi (over 100 stores), Go Sushi, Wok Me, and many others… do NOT hand roll their sushi).

But I’ll explain what that is in a minute. Let’s move onto the second problem most sushi businesses face:

[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Problem #2: Your Staff May Not Hand Roll Sushi Fast Enough Or Well Enough

[op_liveeditor_element data-style=””]

You may be confident hand rolling sushi. But what if OTHER people are helping you run your business? Or what if you have an army of casual and part-time staff who aren’t experienced in making sushi – working in your store?

You may not always be able to find skilled staff who can CONSISTENTLY hand roll sushi to a high standard – whether that’s because they’re new, unfamiliar with sushi, or don’t spend much time in your shop because they only work there part-time.

This can hurt the quality of the sushi produced by your business, HURT your store’s reputation and STOP people from buying from you.

[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Problem #3: Hiring More People To Roll Sushi Is Expensive

[op_liveeditor_element data-style=””]

Hand rolling can be slow, and if you need to make a lot of sushi to feed lots of customers, you’ll need to hire extra helping hands to help you make sushi rolls quickly.

The problem is that you’ll have to pay for these extra people – which can quickly reduce your profit by tens of thousands of dollars or more, every year.

And in some regional areas, this may not even be an option as you may not be able find anyone to help you out!

[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Problem #4: You Have Limited Space In Your Shop

[op_liveeditor_element data-style=””]

If you are thinking about hiring extra people to make more sushi – it may not even be possible.

Extra people take up extra room in your shop. And if you have a small shop, you may not have the bench space for them to work, or the floor space for them to stand.

OR if you haven’t setup a shop yet, you’ll have to factor in extra room for the extra people in the shop – which can balloon your rent costs, and eat through your profits because you’ll need to lease a bigger shop space.

[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Problem #5: You need To Setup Procedures To Keep Sushi Clean, Safe To Eat

[op_liveeditor_element data-style=””]

If you are rolling sushi by hand in your shop, you need to take particular care to keep your bench clean and hygienic, and also make sure your staff’s hands are always clean. This is very important for maintaining your store’s reputation for making sushi that is both delicious AND safe to eat.

The last thing your shop needs is to have a reputation for being “the sushi place that gave me food poisoning.”

[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Problem #6: People Get Sick, Go On Holidays, And Quit

[op_liveeditor_element data-style=””]

People you hire to help you hand roll sushi – will get sick, take holidays, or leave to start their own business. It’s just reality.

People are not machines, and you can’t control them. They may have to take a day off, or they may stop working for you.

And what will you do when that happens?

What will happen to the quality of your sushi when you hire someone new who isn’t that experienced at rolling sushi?

What will happen to your production if you can’t find someone to cover the person who got sick?

How will you protect your business against employees who learn the whole sushi-making process and then choose to go on and start their own sushi business – becoming YOUR COMPETITION, possibly stealing away your business? (Once your employees know how to hand roll sushi properly, there’s absolutely nothing stopping them from going out and starting their own business)

[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Now, Japan has refined food culture – people are very picky about the food they eat.

Unlike people from many Western countries, the Japanese can detect very minute differences in quality and taste between foods and have been trained since childhood to appreciate high quality food.

You can see this in the years of training that sushi apprentices spend to become a sushi chef.

In many sushi bars, apprentices spend years JUST learning how to wash and prepare the rice – BEFORE they are even allowed to touch or prepare the actual ingredients (which can take them many more years to learn after that).

And then it can be another number of years before they are allowed to prepare and make sushi for an important client of the restaurant.

In fact, it is not uncommon for sushi chefs to work for decades under the watchful eye of their master chef (who can be 70, or 80 years old).

It is this kind of dedication to excellence and standard the Japanese hold themselves to.

And it was this kind of standard that the solution to the problems of hand rolling sushi – would have to measure up to.[/text_block]

Secondly, it would have to be a compact solution. In busy cities like Tokyo and Osaka, rent is costly, and any extra room taken up in a sushi shop can skyrocket costs and destroy profitability. The solution to increase the output or sushi would have to take up minimal space in a shop.

And lastly, it would have to consistently make quality sushi that would rival the hand-made sushi made by the best sushi chefs – and satisfy the refined palate and taste of the Japanese customer.

Any sub-par sushi would not be accepted by the Japanese public, and the solution would have to make sushi to an extremely high standard.[/text_block]

So when the need for technology that would help speed up the production of sushi, came – a good base was already there.

Despite this, it would take a few decades of research, development, planning and trial, before the Japanese were able to develop the technology necessary to fulfill all the requirements necessary to help sushi businesses.

But they did end up successfully developing that technology.

The first sushi “robots” were produced in 1981. These unique robots helped automate much of the sushi-making process – helping shops churn out more sushi to feed hungry crowds.

With Japan’s philosophy of “Kaizen”, or continual improvement, sushi robots were continually refined by its original maker, Suzumo – with newer generations of sushi machines developed to automate different processes in the sushi shop.

The machines got faster and faster, better and better. And the quality of the sushi produced by the machine got so good that tens of thousands of shops all around Japan started using them.

Soon, sushi machines were everywhere in Japan, helping sushi shops wash rice, mix rice, sheet rice, roll sushi, cut rolls, make nigiri, and even produce sushi on an industrial scale to stock supermarkets, and feed entire schools!

Once these sushi machines passed Japan’s rigorous testing and acceptance – the word soon spread to other countries, and the machines soon found their way into sushi shops around the world – including Australia.

Despite their common place in sushi shops in Australia and Japan, very few people, even today, are aware of these “secret sushi chefs behind the counter” – machines that work tirelessly to create sushi for millions of people every day.

They are so good, that most people today are not even aware that the sushi they buy at their favourite shop – is made using one of these machines. Look carefully next time you buy some sushi. You might just see one of these machines in the background helping the shop!

Why have they become so popular with sushi business owners?

Because they help anyone, no matter how experienced, to become a “sushi chef” and create top quality sushi that is often ‘mistaken’ for hand made sushi. They are ‘qualified sushi chefs’ that work tirelessly without breaks, never get sick, don’t need to be paid, work over time without complaining, never takes holidays, and will always make great tasting sushi.

They are a way to increase your productivity, save room, lower your labour costs, and create more consistent and hygienic sushi – no matter who is in your shop.

Which means you can run your sushi business more smoothly, and more profitably with sushi machines.[/text_block]

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

-

1

Spray inside of the hopper and shutter blade with rice oil spray (only done once at the beginning of the day)

-

2

Place cooked rice in the hopper.

-

3

Press the green button to initialise the machine and do 2-3 test runs.

-

4

Press the green switch to dispense rice sheet

-

5

Place the nori sheet over the rice sheet

-

6

Remove the rice sheet from the rice board, place ingredients on the rice sheet and hand roll your sushi.

-

1

Spray inside of the hopper and shutter blade with rice oil spray (only done once at the beginning of the day)

-

2

Place cooked rice in the hopper.

-

3

Press the green button to initialise the machine and do 2-3 test runs.

-

4

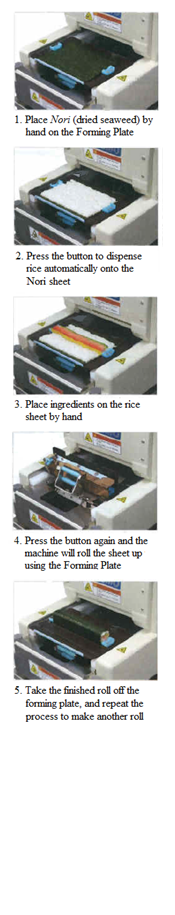

Place the nori seaweed sheet on the forming plate

-

5

Press the green switch to dispense rice sheet

-

6

Place the ingredients on the rice sheet

-

7

Press the start green switch again to roll

-

8

Remove the finished roll from the forming plate or press the “forming” button on the touch screen again if you want to roll it again.

-

1

Spray inside of the hopper and shutter blade with rice oil spray (only done once at the beginning of the day)

-

2

Place cooked rice in the hopper.

-

3

Press the green button to initialise the machine and do 2-3 test runs.

-

4

Press the green switch. A rice sheet will be dispense on the conveyor belt.

-

5

Normal Sushi Roll Operation – Place the nori sheet on the rice sheet (on the far end of the rice sheet)

-

6

Inside Out Sushi Roll Operation – Place the nori sheet on the rice sheet (on the middle of the rice sheet)

-

7

Place the ingredients on

-

8

Press the start green switch again to roll

-

9

Remove the finished roll from the conveyor or press the “forming” button on the touch screen again if you want to roll it again.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.

[op_liveeditor_element data-style=””]

Common Features

[/op_liveeditor_element]

[op_liveeditor_element data-style=””]

[/op_liveeditor_element]

[op_liveeditor_element data-style=””]There seems to be a problem with your OptimizePress API Key.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]

Start Making More Sushi Today

Start Making More Sushi Today

[op_liveeditor_element data-style=””][text_block style=”style_1.png” align=”left”]If you would like:[/text_block][/op_liveeditor_element]

[op_liveeditor_element data-style=””]There seems to be a problem with your OptimizePress API Key.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.[/op_liveeditor_element]

[op_liveeditor_element data-style=””][text_block style=”style_1.png” align=”left”]Then simply click the button below, to be taken to a page where we will get your name, business name, e-mail and telephone number and get in touch to send you through a quote.

Click on the button below now, and be one step closer to having a Suzumo sushi-making machine help transform your sushi business:[/text_block][/op_liveeditor_element]

[op_liveeditor_element data-style=””]There seems to be a problem with your OptimizePress API Key.

Please recheck it is entered correctly and if you still have problems see this guide for help or contact support.[/op_liveeditor_element]

[op_liveeditor_elements][/op_liveeditor_elements]