Universal Molding Conveyor

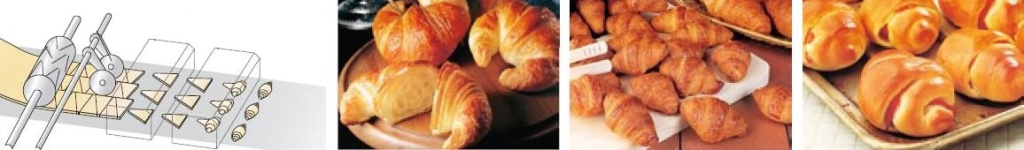

Capable of various types of automated forming.

Used with Rheon Stress Free® Bread Production Lines, automatically forms various products from a dough sheet continuously fed from preceding machine.

The model comes with three different width(MC321, MC322, MC323).

Features

Used with Rheon Stress Free® Bread Production Lines(EZ Table, HM Line, Pastry Production Line), automatically forms croissants, various pastries, sweet buns, table rolls and other products from a dough sheet continuously fed from preceding machine.

Built-in P.M.U.(Product Memory Unit) memorizes production data for up to 50 products. Saved data can be easily recalled at any time.

Double Rotary Cutter Stand, Spot Spray, Press Roller and Curling Unit are standard equipment.

Turner is equipped as an option.(The maximum production speed is 3,000 pcs./hr/row.)

Molding section rolls up all the products from small size to large size perfectly.

There are three types of spraying patterns(spot spraying, continuous spraying, and water dripping.)

Guillotine cutter is selectable for your production needs.

Very quiet guillotine operation with servo motor drive system. (The maximum intermittent cutting speed is 120 cuts/min and 200 cuts/min on continuous cutting.)

Cutters can be placed and removed easily, with air cylinder-operated single-action clamps.

Hygienic-conscious design facilitates cleaning work inside the conveyor construction, such as;

1) Flip-Up molder section.

2) One-Touch setting/releasing belt tensioner.

3) Easily detachable front and end plates on each belt section without tools.

4) Easily detachable conveyor plates on each section without tools.

5) Easily detachable scraper units on rollers and belts without tools.

Specifications

| Model Code | MC321 | MC322 | MC323 |

|---|---|---|---|

| Effective dough sheet width | 400mm | 600mm | 800mm |

For the actual maximum guillotine cutting speed, confirm by running the test with your own dough at the Rheon office near you.