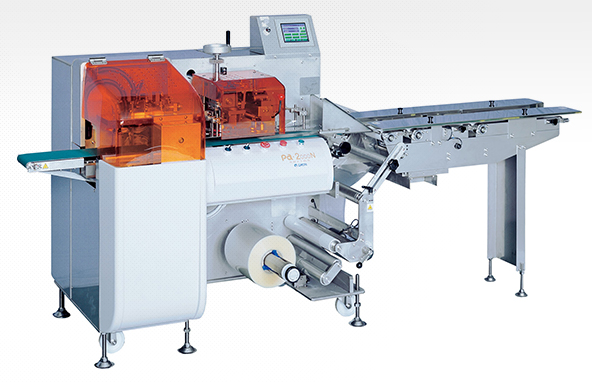

Pa-2605N BX – Compact HFFS Inverted, Box Motion End Seal

Features

- Touch panel control for simple operation.

- Compact body saves floor space.

- Simple design for easy maintenance.

- Various infeed systems can be chosen depending on product.

- 32 items memory for product setting.

- Box motion end sealer type (BX) allows incorporation of oxygen absorber.

- Triple AC servo motor drive system for easy size change.

- Adjustable forming box is supplied as standard.

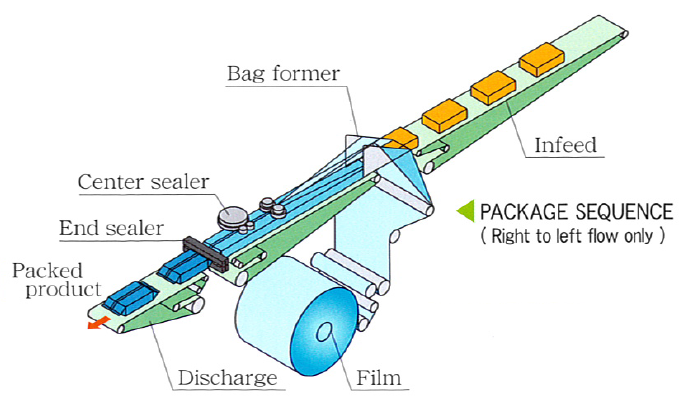

Bottom Film Feed (Inverted)

Inverted Flow Wrappers feed film from below, rather than from above. The product flows on top of the packaging film, and is sealed above. Inverted flow wrappers are ideal for soft, or multipack items that are not easily packaged using normal, top film-feeding flow wrapping machines.

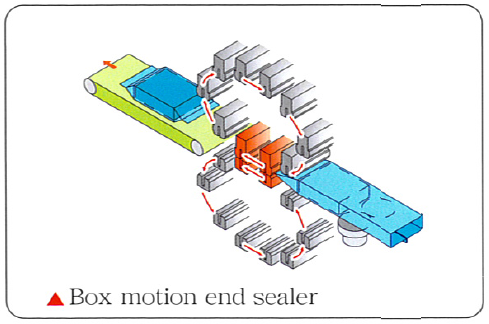

Box Motion End Seal

Box Motion End sealers allow for longer sealing times as the sealing heads travel with the film for a period of time. This leads to better sealing on thicker films and laminates, and in turn, better shelf life and moisture control in products.

Specifications

Inverted machine, Box motion end seal/Rotary end seal

| Model | Pa-2605N (Rotary end seal) | Pa-2605N BX (Box motion end seal) |

|---|---|---|

| Speed | MAX 80packs/min | MAX 60packs/min |

| Main motor | AC servo motor | |

| Film width | MAX400mm | |

| Pack Length | 90~360mm | |

| Product size |

Width : 140mm

Height : 55mm |

Width : 140mm

Height : 75mm |

| Standard paint color | Ivory(Baked paint finish) | |

| Power used | 3PH 200V 5KVA (Differs according to specification) | |

| Machine weight | Approx. 450kg | |

*Specifications are subject to change depending on product and film.

Optional equipment

- Automatic open/close for center sealer (Air operated)

- Product hold down belt.

- Gusset device – neat & compact end seals

- Label head end seal

- Anti-corrosion specification for wet environments

- Various Printers

- Specific model for small fried food products

- Stainless infeed conveyor

- Air extraction hold down sponge

- Hanging display hole punch