Pa2005 BX – Compact HFFS Box Motion End Seal

Features

- Touch panel control for simple operation.

- Compact body saves floor space.

- Simple design for easy maintenance.

- Various infeed systems can be chosen depending on product.

- 32 items memory for product setting.

- Box motion end sealer type (BX) allows incorporation of oxygen absorber.

- Triple AC servo motor drive system for easy size change.

- Adjustable forming box is supplied as standard.

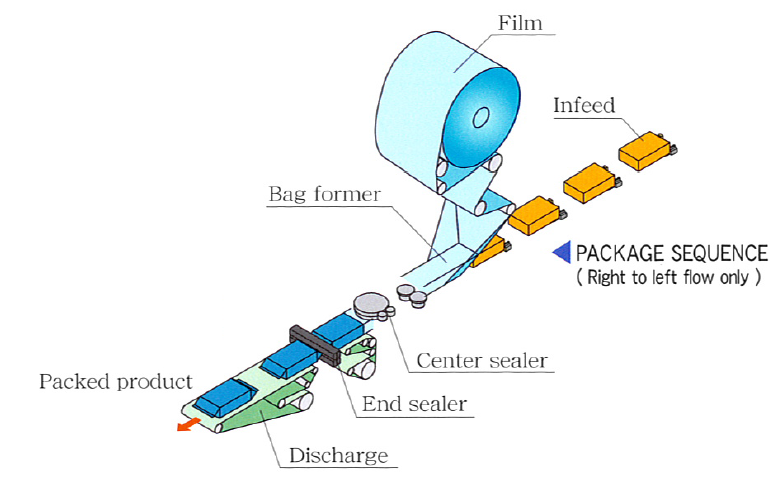

Top Film Feed

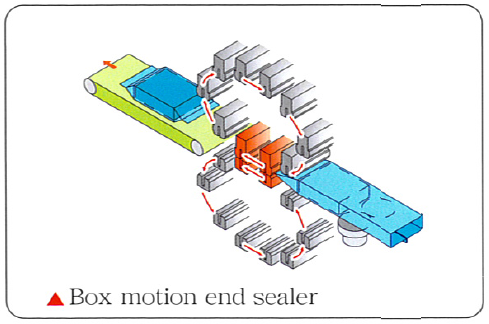

Box Motion End Seal

Box Motion End sealers allow for longer sealing times as the sealing heads travel with the film for a period of time. This leads to better sealing on thicker films and laminates, and in turn, better shelf life and moisture control in products.

Specifications

Top film feed machine, Box motion end seal/Rotary end seal

| Model | Pa-2005N (Rotary end seal) | Pa-2005N BX (Box motion end seal) |

|---|---|---|

| Speed | MAX 100packs/min | MAX 60packs/min |

| Main motor | AC servo motor | |

| Film width | MAX400mm | |

| Pack Length | 90~360mm | |

| Product size |

Width : 140mm Height : 55mm |

Width : 140mm Height : 75mm |

| Standard paint color | Ivory(Baked paint finish) | |

| Power used | 3PH 200V 5KVA (Differs according to specification) | |

| Machine weight | Approx. 450kg | |

*Specifications are subject to change depending on product and film.

Optional equipment

- Automatic open/close for center sealer (Air operated)

- Product hold down belt.

- Gusset device – neat & compact end seals

- Label head end seal

- Anti-corrosion specification for wet environments

- Various Printers

- Stainless infeed conveyor

- Air extraction hold down sponge

- Hanging display hole punch