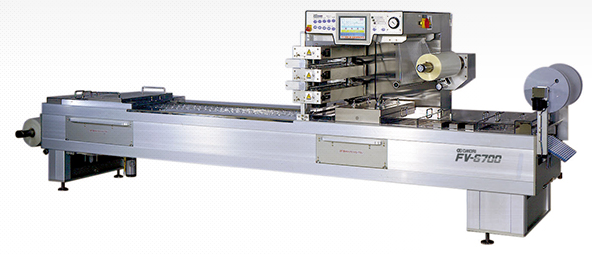

FV Series

Features

- A machine capable of producing many different pack styles.

- 10 product memory for one-touch, easy size change.

- "Roller Drawer" style for instant size change for forming and vacuum chambers available as option.

- Base film drive by high accuracy servo motor allowing precise (0.1mm) pitch changes.

- Base and lid film feed roller set up assures stable film unwinding with stable tension regardless of roll diameter.

- Rotary date stamping (hot printer) eliminates type change (2 step date stamping with type change available as option).

- Multiple wrapping styles such as Vacuum pack, Gas pack, Blister pack, Hot pack, steam shrink wrapping, etc. are available.

- Clear and understandable machine status display with fault alarm allowing normal operation to be restored quickly.

- The system is designed for factory automation and high efficiency.

Specifications

High spec type

| Model | FV6700 | FV6800 (High-speed specification) |

|---|---|---|

| Speed (Max.) |

Vacuum pack : 10 cycles /min Gas pack : 10 cycles /min(MAX) Varies depending on condition such as products & trim cutting |

Vacuum pack : 20 cycles /min Gas pack : 20 cycles /min(MAX) Varies depending on condition such as products & trim cutting |

| Width of base film |

AType : 390~470mm(standard) BType : 470~550mm(wide width) |

|

| Film used |

Upper : Heat sealable stretchable oriented plastic films Lower : Thermo-formable and heat sealable non oriented plastic films Maximum : 370mm |

|

| Draw depth |

Normal : 70mm Conditioned : 60mm(MAX) |

|

| Products | Foods in general (solid, paste, liquid), General goods, Industrial goods | |

| Main unit Total Length |

4,660mm(standard) 5,660mm(1,000mm Long) 6,660mm(2,000mm Long) Intermediate Length-consultation required. |

|

| Forming systems | Air-assist forming method by hot-plate | Servo drive type forming method |

| Seal method | Heat sealing method | |

| Marking alignment | The penetration type is usually employed. (The reflection type is also possible) | |

| Film feeding | Servo motor driven intermittent feeding method | |

| Cross cutting system | Cylinder driven slide-cut method | |

| Longitudinal cutting system | Direct-drive rotating blade | |

| Film scrap remover | Vacuum & winder or cutting type | |

| Air |

0.6Mpa Approx. 100litere/shot *(Differs depending on the specification.) |

|

| Cooling water | Over 0.25Mpa 4~5liter/min | |

| Power used | 3PH AC200V 12KVA ※(Differs depending on the specification.) | |

| Machine weight | Approx. 1,300kg | |

*Specifications are subject to change depending on product and pack characteristics.

Optional equipment

- Forming/Vacuum Box Roller Drawer type

- Overall Trimming device

- Plug assist forming device

- Additional horizontal cutter device

- Bottom film print registration device

- Additional longitudinal cutter device

- Gas flushing specification

- Longitudinal cutter perforated line cutting

- Skin pack specification

- Edge position controller (bobbin swing type)

- Multi-lane specification

- Discharge belt conveyor

- Cooling press system

- Discharge transfer device

- Date stamping device

- Various automatic product feeders

- Rounded corners cross-cut system

- Vacuum pump

- Rounded corners slide device

- Mechanical booster

- I-notch cutter system

- Air compressor